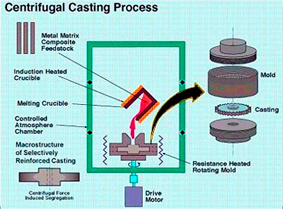

In Centrifugal Casting , A Permanent Metal Mold is rotated continuously on its own axis at high speed as the molten metal is poured.The molten metal is centrifugally thrown towards the inside mold wall, where it solidifies after cooling.The Casting is usually a fine rained casting.Vertical Centrifugal Casting Machine is ideal for Gearblanks.

Advantages of centrifugal casting

Centrifugal casting has certain advantages which can not be achieved by other methods of casting, for example:

- High wear resistance

- High metal density.

- No blisters.

- Centrifugal castings have not non metallic inclusions and slag.